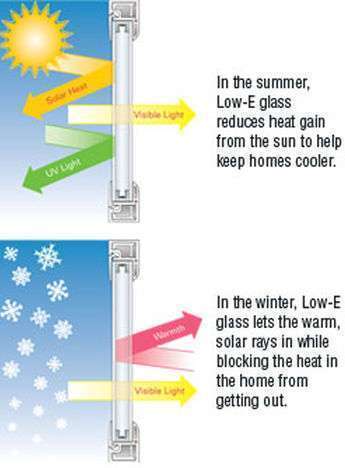

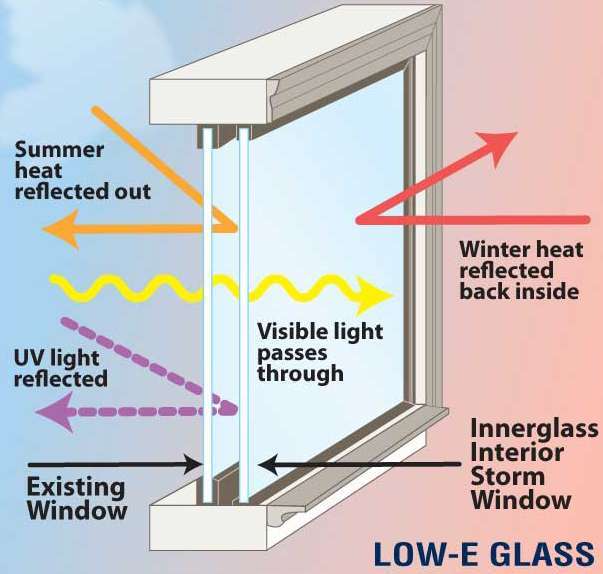

The ability of a material to radiate energy is known as emissivity. This is where low emissivity or Low-E glass coatings come into play. Low-E glass has a microscopically thin, transparent coating – it is much thinner than a human hair – that reflects long-wave infrared energy (or heat). Some Low-E’s also reflect significant amounts of short-wave solar infrared energy.

Difference of IGU with Low-E glass and without Low-E glass:

Center-of-glass values of insulated glass units with and without Low-E coatings. When heat or light energy is absorbed by glass, it is either convected away by moving air or reradiated by the glass surface. The ability of a material to radiate energy is called its emissivity.

Advantages of Low-E glass in IGU:

- Improves the energy-efficiency of your home/office.

- Reduces the amount of energy used.

- Saves you money on your heating bills.

- More effective than single glazing or standard double glazing

- Provides you with the quality and reassurance you would expect from a leading brand.

Types of Low-E Glass:

There are two types of Low-E glass: hard coat and soft coat. As you might imagine, they have different properties. In fact, they actually look different.

Hard coat Low-E glass is manufactured by pouring a thin layer of molten tin onto a sheet of glass while the glass is still slightly molten. The tin actually becomes “welded” to the glass. This process makes it difficult or “hard” to scratch or remove the tin. Often this glass has a blueish tint to it.

Soft coat Low-E glass, on the other hand, involves the application of silver, zinc or tin to glass in a vacuum. The glass enters a vacuum chamber filled with an inert gas which is electrically charged. The electricity combined with the vacuum allows molecules of metal to sputter onto the glass. The coating is fairly delicate or “soft.”