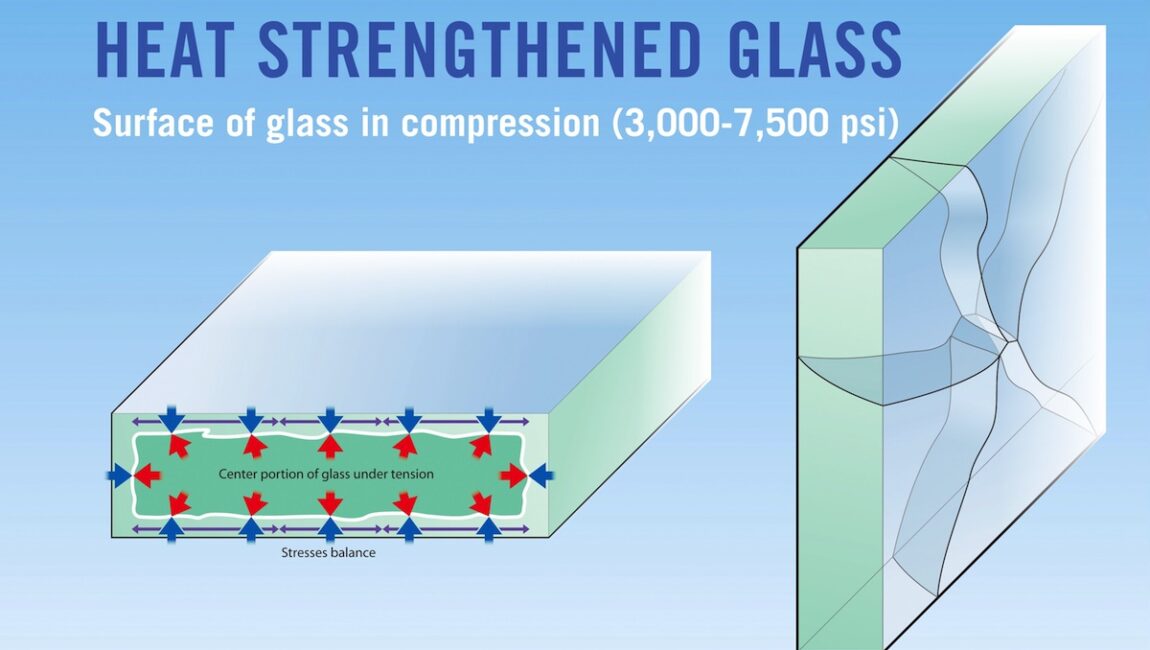

Heat Strengthened Glass

Heat Strengthened Glass (HST) has a mechanical strength of about twice that of annealed (float) glass and if broken, breaks into large pieces from edge to edge and does not fracture into small fragments like tempered safety glass.

For glass to be considered HST, this compressive stress on the surface of the glass should be from 3,500 psi to 7,500 psi. This breakage characteristic allows the glass to remain in the window frame as the large pieces support each other in the opening

Heat Strengthened Glass also provides resistance to thermal breakage caused by heat build-up in spandrel situations and the probability of nickel sulfide inclusions inducing spontaneous breakages in heat strengthened glass is practically non-existent.

HST is often used in laminated glass, as it allows better interlayer adhesion than toughened glass due to the flatter nature of the heat strengthened product. This flatter finish also results in less optical distortion in building façades. As a result of the reasons above, heat strengthened glass is often used in curtain wall façades of buildings, in both the vision and spandrel applications.